How to save money with retention packaging

Updated 7 November 2025.

Retention e-commerce packaging presents an innovative approach for businesses aiming to cut costs and minimise the use of void fill materials. Gaining a solid understanding of how retention packaging works, and its wide-ranging advantages, is a smart first step towards streamlining your packaging strategy. In this article, we explore the relationship between void fill consumption and packaging expenses, offer practical strategies for reducing void fill, and provide guidance on adopting retention packaging in your operations.

Understanding Retention E-commerce Packaging

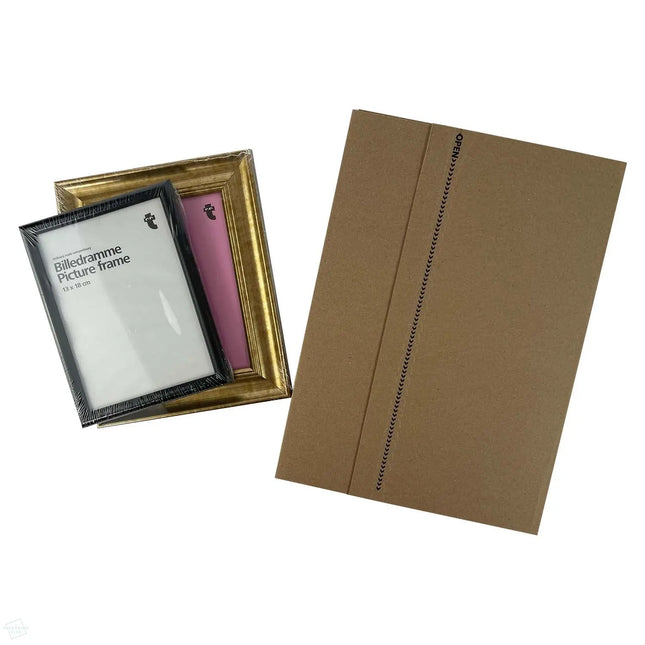

Retention packaging plays a vital role in securing items during delivery. Unlike traditional methods reliant on excessive cushioning, this solution uses custom-fit inserts to immobilise products, making shipping both safer and more economical.

Picture ordering a fragile item online. Instead of receiving it surrounded by a jumble of bubble wrap or packing peanuts, the product arrives snugly fitted within a tailored insert. This not only enhances protection but also reduces waste and improves the overall presentation.

The Fundamentals of Retention Packaging

This packaging method employs precisely engineered inserts to keep products firmly in place. These can be customised to accommodate various shapes and sizes, ensuring a tight fit without the need for supplementary padding.

Foam inserts, for example, are moulded to match the product’s dimensions, acting as shock absorbers during transit. Corrugated cardboard inserts are another popular choice, offering durability and excellent structural support without adding unnecessary bulk.

What sets retention packaging apart is its adaptability. It can be designed to accommodate multiple items or different versions of the same product, allowing companies to standardise packaging and reduce inventory complexity.

The Advantages of Retention Packaging

Beyond reducing packaging spend, retention packaging delivers tangible sustainability benefits. By limiting the need for disposable fill materials, it lowers environmental impact and aligns with growing consumer demand for eco-conscious practices.

It also enhances the customer experience by ensuring items arrive intact and well-presented, which helps reduce returns and boost brand perception. Furthermore, because these packages are typically smaller and lighter, they can significantly cut down on shipping charges, an important factor for e-commerce businesses handling large volumes.

Well-designed retention packaging creates a positive first impression. A neatly organised, secure parcel communicates professionalism and care, potentially encouraging repeat purchases.

In short, retention e-commerce packaging offers a smart, sustainable way to protect goods in transit, cut waste, and improve customer satisfaction, all while helping businesses reduce costs and operate more efficiently.

The Link Between Void Fill and Packaging Costs

Excessive use of void fill can drive up packaging expenses. While cushioning plays a role in protecting fragile items, over-reliance adds unnecessary cost and inefficiencies throughout the supply chain.

Though materials like bubble wrap may appear inexpensive, their cumulative impact—including storage, labour, and waste, can be significant. Space used to store bulky fillers could be better allocated, while the time spent packing each order adds up quickly in high-volume settings.

The Hidden Costs of Void Fill

Beyond direct costs, there are less obvious drawbacks. Non-biodegradable fillers contribute to plastic waste and can tarnish a brand’s environmental credentials. Moreover, overstuffed packaging can cause internal pressure or shifting, increasing the risk of damage.

Customers may also perceive excessive void fill as wasteful, negatively affecting their view of your brand. In contrast, efficient, sustainable packaging solutions tend to resonate more positively with today’s eco-aware shoppers.

How Excessive Void Fill Affects Profitability

Overusing filler materials increases not just material and labour costs, but also shipping expenses- particularly where volumetric pricing applies. Larger parcels take up more space in warehouses and delivery vehicles, further inflating logistics overheads.

By adopting smarter approaches such as retention packaging, businesses can eliminate unnecessary padding while still keeping products secure. This not only saves money but also improves packing consistency and overall operational efficiency.

Environmentally friendly filler alternatives, such as biodegradable or recyclable options, offer a middle ground. While still protective, they reduce environmental impact and appeal to sustainability-conscious consumers, potentially boosting brand loyalty.

Ultimately, understanding how void fill usage affects costs can help businesses fine-tune their packaging approach, reducing expenditure, improving storage efficiency, and creating a more satisfying experience for customers.

Strategies for Minimising Void Fill

Reducing the need for void fill requires a combination of better design, smarter material choices, and process improvements. By focusing on right-sized packaging and built-in product protection, businesses can achieve both cost and environmental benefits.

Utilising FlyPak for Built-in Retention and Speed

FlyPak is a paper-based postal solution featuring integrated retention wings to secure products firmly in place. Designed specifically for e-commerce, it negates the need for additional cushioning, making it ideal for cosmetics, tech accessories, health items, and curated gift sets.

FlyPak ships flat and assembles rapidly. Staff can insert the product, fold the internal flaps, and seal the package in seconds - eliminating bubble wrap or kraft paper. This streamlined approach enhances productivity and consistency, especially in high-volume dispatch environments.

For brands focused on reducing waste, speeding up fulfilment, and delivering a polished unboxing experience, FlyPak provides a ready-made, all-in-one solution.

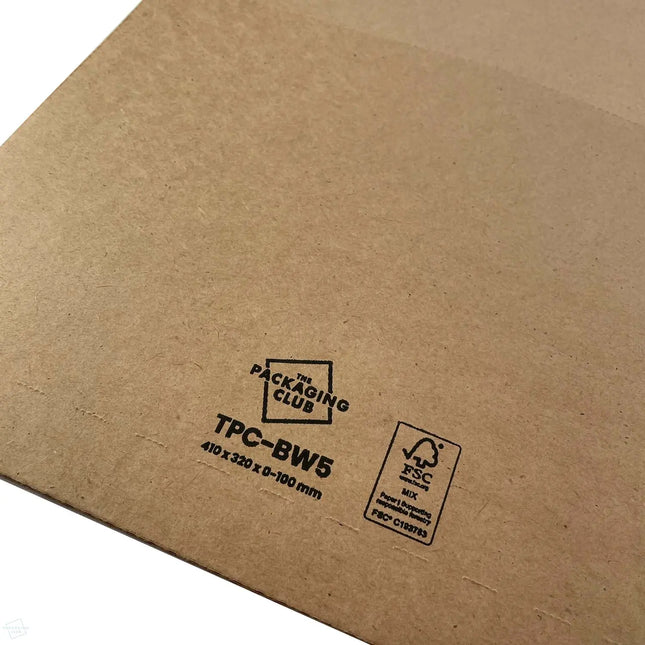

Optimising Package Dimensions

Choosing packaging that closely matches product size and shape is among the most effective ways to reduce filler usage. Custom solutions like retention packaging not only offer a tailored fit but also minimise shifting, thereby eliminating the need for excessive padding.

Exploring Sustainable Void Fill Alternatives

In cases where some cushioning is unavoidable, eco-friendly options like biodegradable air pillows or natural kraft paper void fill provide excellent protection with a lower environmental footprint. Switching to these materials supports sustainability goals while maintaining product safety.

In cases where some cushioning is unavoidable, eco-friendly options like biodegradable air pillows or natural kraft paper void fill provide excellent protection with a lower environmental footprint. Switching to these materials supports sustainability goals while maintaining product safety.

Looking to develop your own custom retention or e-commerce packaging? Speak to our team about bespoke packaging solutions that reduce waste, speed up fulfilment, and protect your products in transit.